Medium Voltage XLPE Insulated Overall Screened Cable to IEC 60502-2

Application

These cables are suitable for installation mostly in power supply stations, indoors and in cable ducts, outdoors, underground and in water as well as for installation on cable trays for industries.

Standards

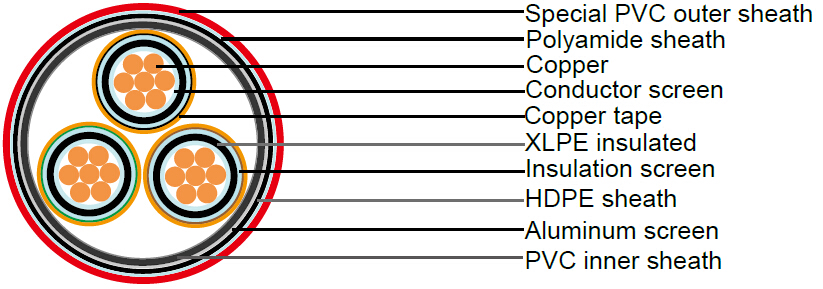

Cable Construction

Construction

| Conductor |

Stranded bare copper (class 2) |

| Conductor screen |

This will be an extruded layer of semi-conducting crosslinkable compound applied under simultaneous triple extrusion process over the conductor along with the insulation and the insulation screen |

| Insulation |

XLPE |

| Insulation screen |

This will be a layer of semi-conducting crosslinkable compound which will be applied by triple extrusion process over the insulation |

| Core identification |

1 Core: Natural

3 Cores: Black, Green, Brown |

| Inner sheath |

PVC Color black |

| Overall screen |

Aluminum/polyethylene tape |

| Sheath |

HDPE Color: black |

| Special sheath (intermediate sheath) |

Polyamide |

| Outer sheath |

Special PVC. Color: red. U.V resistance can be offered upon request |

Properties

| Fire retardance |

IEC 60332-3-22 |

| Operating temperature |

-20~60°C |

| Max. conductor operating temperature |

90°C |

| Chemical resistance |

Aliphatic and aromatic hydrocarbon resistance |

1 Core

| Conductor Corss-section |

Diameter over Insulation |

Diameter over Screen |

Diameter over Inner Sheath |

Diameter over Intermediate Sheath |

Min. O.D. |

Max. O.D. |

Approx.Weight |

Rated Voltage Uo/ U(Um) |

| (mm2) |

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

(kg/km) |

(kv) |

| 25 |

12.3 |

13.7 |

15.6 |

19.9 |

22.6 |

24.9 |

778 |

3.6 / 6 (7.2) |

| 35 |

13.3 |

14.7 |

16.6 |

20.9 |

23.6 |

26.0 |

892 |

3.6 / 6 (7.2) |

| 50 |

14.4 |

15.8 |

17.7 |

22.1 |

24.7 |

27.3 |

1037 |

3.6 / 6 (7.2) |

| 70 |

16.0 |

17.4 |

19.4 |

23.7 |

26.5 |

29.2 |

1285 |

3.6 / 6 (7.2) |

| 95 |

17.55 |

19.0 |

20.9 |

25.2 |

27.9 |

30.8 |

1567 |

3.6 / 6 (7.2) |

| 120 |

19.06 |

20.5 |

22.4 |

26.7 |

29.6 |

32.6 |

1849 |

3.6 / 6 (7.2) |

| 150 |

20.37 |

21.8 |

23.7 |

28.0 |

30.8 |

34.0 |

2130 |

3.6 / 6 (7.2) |

| 185 |

22.05 |

23.5 |

25.4 |

29.7 |

32.7 |

36.1 |

2532 |

3.6 / 6 (7.2) |

| 240 |

24.6 |

26.0 |

28.5 |

32.8 |

35.9 |

39.6 |

3194 |

3.6 / 6 (7.2) |

| 300 |

27.4 |

28.8 |

31.2 |

35.5 |

38.7 |

42.7 |

3871 |

3.6 / 6 (7.2) |

| 400 |

30.9 |

32.3 |

34.7 |

39.0 |

42.3 |

46.7 |

4773 |

3.6 / 6 (7.2) |

| 500 |

35.4 |

36.8 |

39.6 |

43.9 |

47.2 |

52.1 |

5997 |

3.6 / 6 (7.2) |

| 630 |

39.8 |

41.2 |

42.8 |

47.1 |

50.5 |

55.7 |

7455 |

3.6 / 6 (7.2) |

| 25 |

14.1 |

15.5 |

17.4 |

21.7 |

24.3 |

26.9 |

850 |

6 / 10 (12) |

| 35 |

15.1 |

16.5 |

18.4 |

22.7 |

25.5 |

28.1 |

984 |

6 / 10 (12) |

| 50 |

16.2 |

17.6 |

19.5 |

23.8 |

26.6 |

29.3 |

1132 |

6 / 10 (12) |

| 70 |

17.8 |

19.2 |

21.3 |

25.6 |

28.5 |

31.5 |

1397 |

6 / 10 (12) |

| 95 |

19.35 |

20.8 |

22.7 |

27.0 |

29.9 |

33.0 |

1675 |

6 / 10 (12) |

| 120 |

20.86 |

22.3 |

24.2 |

28.5 |

31.5 |

34.8 |

1965 |

6 / 10 (12) |

| 150 |

22.17 |

23.6 |

25.5 |

29.8 |

32.8 |

36.2 |

2254 |

6 / 10 (12) |

| 185 |

23.85 |

25.3 |

27.6 |

31.9 |

35.0 |

38.6 |

2692 |

6 / 10 (12) |

| 240 |

26.2 |

27.6 |

30.1 |

34.4 |

37.4 |

41.3 |

3298 |

6 / 10 (12) |

| 300 |

28.6 |

30.0 |

32.4 |

36.7 |

39.9 |

44.0 |

3954 |

6 / 10 (12) |

| 400 |

31.7 |

33.1 |

35.5 |

39.8 |

43.1 |

47.5 |

4831 |

6 / 10 (12) |

| 500 |

35.8 |

37.2 |

40.0 |

44.3 |

47.6 |

52.5 |

6030 |

6 / 10 (12) |

| 630 |

40.2 |

41.6 |

43.2 |

47.5 |

50.9 |

56.2 |

7491 |

6 / 10 (12) |

| 25 |

16.3 |

17.7 |

19.6 |

23.9 |

26.7 |

29.4 |

968 |

8.7 / 15 (17.5) |

| 35 |

17.3 |

18.7 |

20.6 |

24.9 |

27.6 |

30.5 |

1097 |

8.7 / 15 (17.5) |

| 50 |

18.4 |

19.8 |

21.8 |

26.1 |

29.0 |

32.0 |

1269 |

8.7 / 15 (17.5) |

| 70 |

20.0 |

21.4 |

23.4 |

27.7 |

30.6 |

33.7 |

1510 |

8.7 / 15 (17.5) |

| 95 |

21.55 |

23.0 |

24.9 |

29.2 |

32.2 |

35.5 |

1814 |

8.7 / 15 (17.5) |

| 120 |

23.06 |

24.5 |

26.4 |

30.7 |

33.7 |

37.1 |

2097 |

8.7 / 15 (17.5) |

| 150 |

24.37 |

25.8 |

28.1 |

32.4 |

35.5 |

39.2 |

2439 |

8.7 / 15 (17.5) |

| 185 |

26.05 |

27.5 |

29.8 |

34.1 |

37.2 |

41.0 |

2839 |

8.7 / 15 (17.5) |

| 240 |

28.4 |

29.8 |

32.3 |

36.6 |

39.8 |

43.9 |

3472 |

8.7 / 15 (17.5) |

| 300 |

30.8 |

32.2 |

34.6 |

38.9 |

42.2 |

46.5 |

4133 |

8.7 / 15 (17.5) |

| 400 |

33.9 |

35.3 |

38.1 |

42.4 |

45.8 |

50.5 |

5068 |

8.7 / 15 (17.5) |

| 500 |

38.0 |

39.4 |

42.2 |

46.5 |

50.0 |

55.1 |

6242 |

8.7 / 15 (17.5) |

| 630 |

42.4 |

43.8 |

45.4 |

49.7 |

53.3 |

58.7 |

7714 |

8.7 / 15 (17.5) |

| 35 |

19.3 |

20.7 |

22.6 |

26.9 |

29.8 |

32.8 |

1214 |

12 / 20 (24) |

| 50 |

20.4 |

21.8 |

23.7 |

28.0 |

30.8 |

34.0 |

1369 |

12 / 20 (24) |

| 70 |

22.0 |

23.4 |

25.4 |

29.7 |

32.7 |

36.1 |

1640 |

12 / 20 (24) |

| 95 |

23.55 |

25.0 |

27.3 |

31.6 |

34.7 |

38.3 |

1987 |

12 / 20 (24) |

| 120 |

25.06 |

26.5 |

28.8 |

33.1 |

36.2 |

39.9 |

2276 |

12 / 20 (24) |

| 150 |

26.37 |

27.8 |

30.1 |

34.4 |

37.6 |

41.5 |

2592 |

12 / 20 (24) |

| 185 |

28.05 |

29.5 |

31.8 |

36.1 |

39.3 |

43.3 |

2999 |

12 / 20 (24) |

| 240 |

30.4 |

31.8 |

34.3 |

38.6 |

41.9 |

46.2 |

3638 |

12 / 20 (24) |

| 300 |

32.8 |

34.2 |

36.6 |

40.9 |

44.3 |

48.9 |

4314 |

12 / 20 (24) |

| 400 |

35.9 |

37.3 |

40.1 |

44.4 |

47.9 |

52.9 |

5257 |

12 / 20 (24) |

| 500 |

40.0 |

41.4 |

44.3 |

48.6 |

52.2 |

57.6 |

6483 |

12 / 20 (24) |

| 630 |

44.4 |

45.8 |

47.4 |

51.7 |

55.4 |

61.1 |

7930 |

12 / 20 (24) |

| 25 |

26.3 |

27.7 |

30.0 |

34.3 |

37.3 |

41.2 |

1636 |

18 / 30 (36) |

| 50 |

25.4 |

26.8 |

29.1 |

33.4 |

36.5 |

40.2 |

1740 |

18 / 30 (36) |

| 70 |

27.0 |

28.4 |

30.8 |

35.1 |

38.3 |

42.3 |

2034 |

18 / 30 (36) |

| 95 |

28.55 |

30.0 |

32.3 |

36.6 |

39.8 |

43.9 |

2346 |

18 / 30 (36) |

| 120 |

30.06 |

31.5 |

33.8 |

38.1 |

41.4 |

45.7 |

2669 |

18 / 30 (36) |

| 150 |

31.37 |

32.8 |

35.1 |

39.4 |

42.7 |

47.1 |

2971 |

18 / 30 (36) |

| 185 |

33.05 |

34.5 |

36.8 |

41.1 |

44.5 |

49.1 |

3416 |

18 / 30 (36) |

| 240 |

35.4 |

36.8 |

39.7 |

44.0 |

47.5 |

52.4 |

4115 |

18 / 30 (36) |

3 Cores

| Conductor Corss-section |

Diameter over Insulation |

Diameter over Screen |

Diameter over Inner Sheath |

Diameter over Intermediate Sheath |

Min. O.D. |

Max. O.D. |

Approx.Weight |

Rated Voltage Uo/ U(Um) |

| (mm2) |

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

(kg/km) |

(kv) |

| 25 |

12.3 |

13.7 |

33.1 |

37.4 |

40.5 |

44.7 |

2760 |

3.6 / 6 (7.2) |

| 35 |

13.3 |

14.7 |

35.3 |

39.6 |

42.9 |

47.3 |

3228 |

3.6 / 6 (7.2) |

| 50 |

14.4 |

15.8 |

38.1 |

42.4 |

45.8 |

50.5 |

3835 |

3.6 / 6 (7.2) |

| 70 |

16.0 |

17.4 |

41.8 |

46.1 |

49.6 |

54.7 |

4788 |

3.6 / 6 (7.2) |

| 95 |

17.55 |

19.0 |

45.1 |

49.4 |

53.0 |

58.4 |

5856 |

3.6 / 6 (7.2) |

| 120 |

19.06 |

20.5 |

48.8 |

53.1 |

56.9 |

62.8 |

6998 |

3.6 / 6 (7.2) |

| 150 |

20.37 |

21.8 |

51.7 |

56.0 |

59.9 |

66.1 |

8092 |

3.6 / 6 (7.2) |

| 185 |

22.05 |

23.5 |

55.4 |

59.7 |

63.7 |

70.3 |

9585 |

3.6 / 6 (7.2) |

| 25 |

14.1 |

15.5 |

37.1 |

41.4 |

44.8 |

49.4 |

3213 |

6 / 10 (12) |

| 35 |

15.1 |

16.5 |

39.6 |

43.9 |

47.2 |

52.1 |

3723 |

6 / 10 (12) |

| 50 |

16.2 |

17.6 |

42.1 |

46.4 |

49.9 |

55.0 |

4333 |

6 / 10 (12) |

| 70 |

17.8 |

19.2 |

45.8 |

50.1 |

53.8 |

59.4 |

5343 |

6 / 10 (12) |

| 95 |

19.35 |

20.8 |

49.5 |

53.8 |

57.6 |

63.6 |

6516 |

6 / 10 (12) |

| 120 |

20.86 |

22.3 |

52.8 |

57.1 |

61.0 |

67.3 |

7619 |

6 / 10 (12) |

| 150 |

22.17 |

23.6 |

55.7 |

60.0 |

64.0 |

70.6 |

8741 |

6 / 10 (12) |

| 185 |

23.85 |

25.3 |

59.4 |

63.7 |

67.8 |

74.8 |

10259 |

6 / 10 (12) |

| 25 |

16.3 |

17.7 |

42.3 |

46.6 |

50.1 |

55.2 |

3843 |

8.7 / 15 (17.5) |

| 35 |

17.3 |

18.7 |

44.5 |

48.8 |

52.4 |

57.8 |

4380 |

8.7 / 15 (17.5) |

| 50 |

18.4 |

19.8 |

46.9 |

51.2 |

54.9 |

60.6 |

5022 |

8.7 / 15 (17.5) |

| 70 |

20.0 |

21.4 |

51.8 |

55.3 |

59.1 |

65.2 |

6117 |

8.7 / 15 (17.5) |

| 35 |

19.3 |

20.7 |

49.3 |

53.6 |

57.4 |

63.3 |

5086 |

12 / 20 (24) |

| 50 |

20.4 |

21.8 |

51.7 |

56.0 |

59.9 |

66.1 |

5763 |

12 / 20 (24) |

| 70 |

22.0 |

23.4 |

55.4 |

59.7 |

63.7 |

70.3 |

6856 |

12 / 20 (24) |